Platform

Products

Solutions

Services

Research

Cases

About US

LinkedData Smart Factory Platform

LinkedData Smart Factory Base

MOM

Manufacturing Execution System (MES)

Warehouse Management System (WMS)

AGV Control and Dispatch System

IOT Equipment Data Collection

SCP

Customer Planning

Production Planning

Supplier Relationship Management

LPS

Shopfloor Management Cycle(SMC)

Digital Shop Floor Management System(SFM)

Cycle Time Analysis

Value Stream Mapping(Digital VSM)

Smart Standardization

Total Productive Maintenance (Digital TPM)

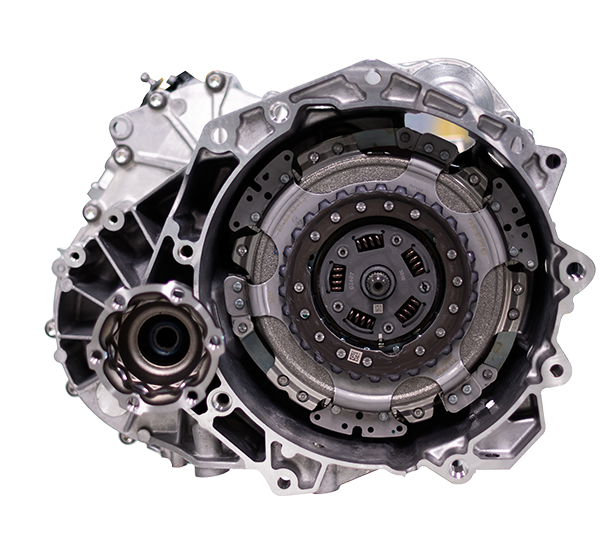

Automotive & Parts Industry Solutions

Robot Integration Solotions

48V BMS Solution

LinkedData News

LinkedData Introduction

Join LinkedData

0510-8521 1230

0510-8521 1230