A Leading Public Company Partners with LinkedData to Launch Intelligent and Integrated Quality Management System

Background

In the field of electrical control and safety components, quality is not only a fundamental requirement of products but also the core driver for winning customer trust and maintaining market leadership. As an industry leader, this public company has consistently adhered to the principle of “quality first,” relentlessly pursuing product reliability and consistency.

With increasingly complex supply chains and rising customer demands for safety standards, delivery efficiency, and traceability, the company aims to build an end-to-end, integrated, and intelligent quality management system through digitalization—achieving quality excellence across the entire product lifecycle.

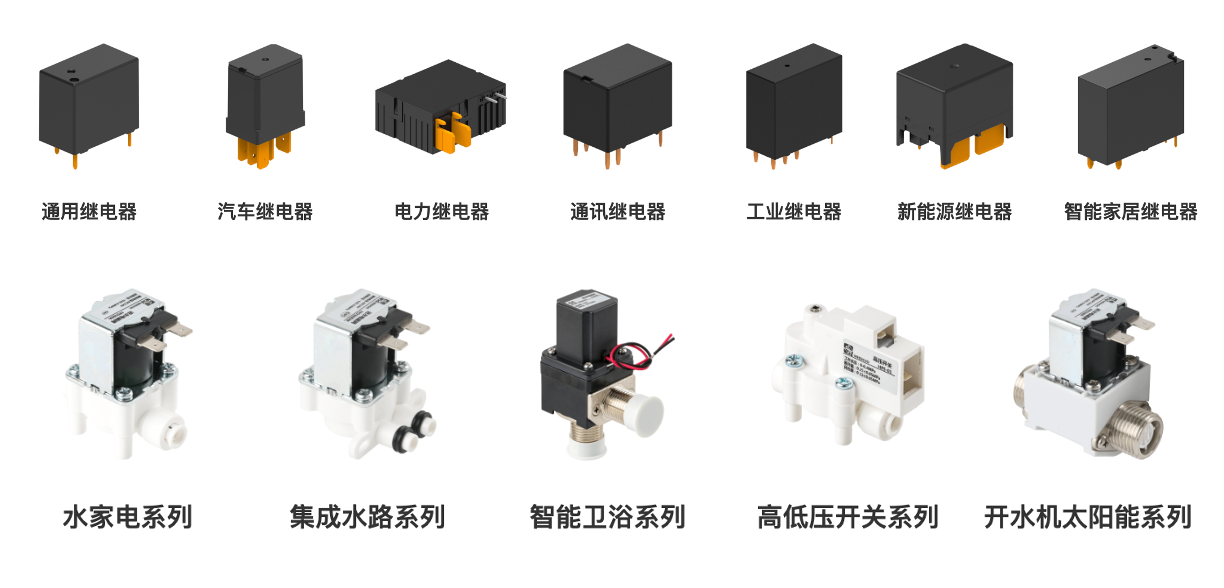

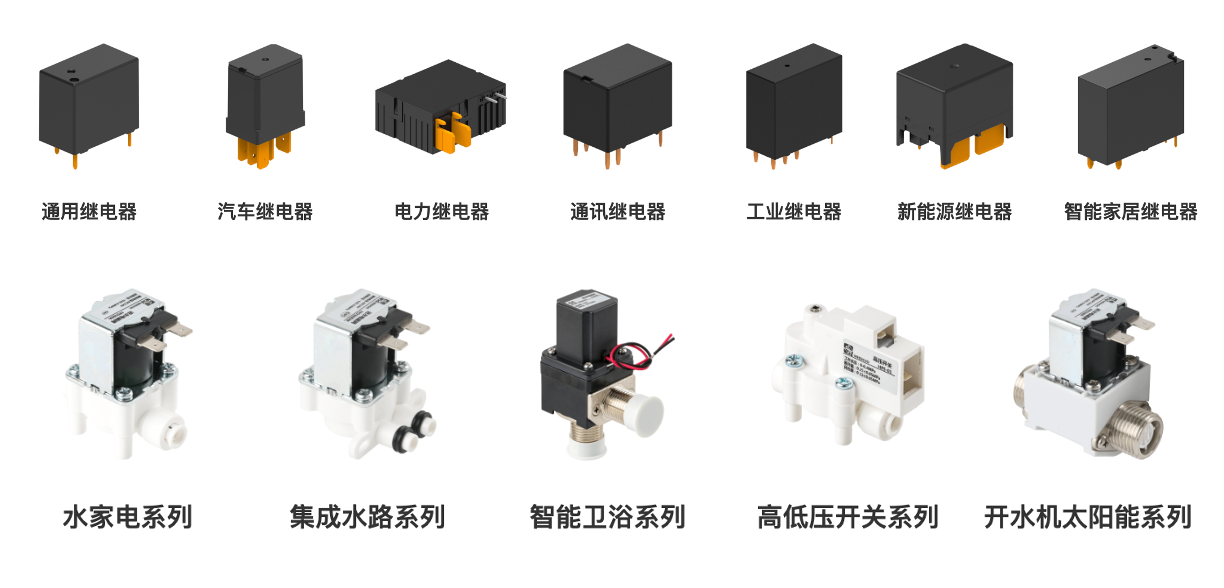

Customer’s Core Products

Against this backdrop, LinkedData partnered with the customer to jointly build an integrated quality management system. The system covers R&D, supply chain, manufacturing, and after-sales, enabling end-to-end consistency in quality management. Driven by data and targeting zero defects, it establishes a quality loop of “trace–contain–alert–prevent,” providing strong support for sustainable quality competitiveness.

Core Advantages of the Integrated Quality Management System

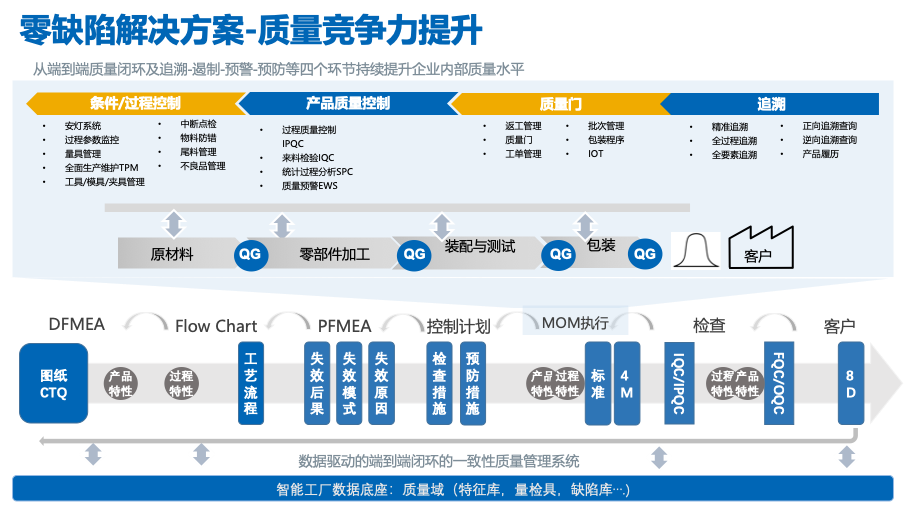

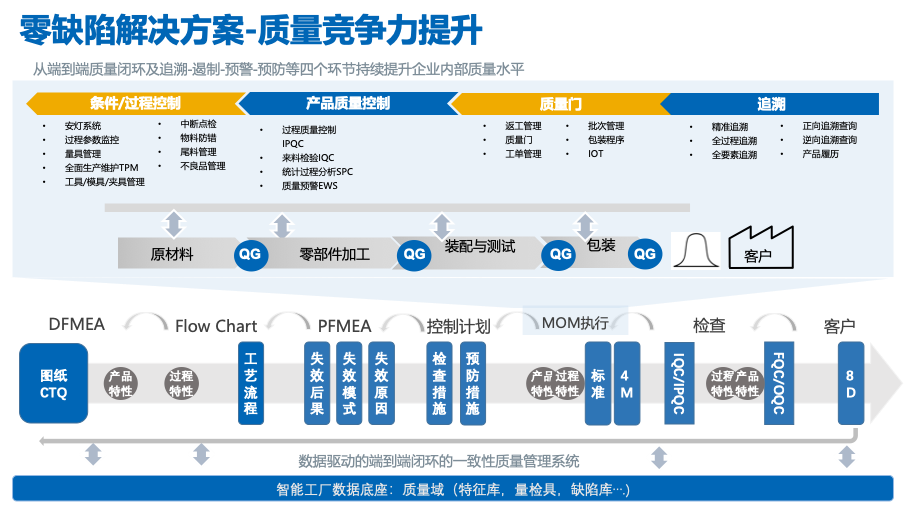

LinkedData Zero-Defect Solution – Elevating Quality Competitiveness

End-to-End Quality Management Integration

The system enables integrated, digitalized management across marketing quality, design quality, supplier quality, process quality, and after-sales quality—covering the complete product lifecycle. By breaking down silos, the customer gains cross-departmental collaboration on a unified platform, avoiding the fragmented management and scattered data of the past.

Consistent Quality Data

Built on a unified data foundation (UDM), the system establishes a universal quality data model spanning R&D, manufacturing, and after-sales. Data flows intelligently and seamlessly between modules, ensuring enterprise-wide consistency and laying a solid data foundation.

Intelligent Product-Level Quality Improvement Loop

Leveraging consistent data models, the system enables efficient forward quality planning. When internal or external quality issues arise, it can perform intelligent root-cause analysis using full-factor data (quality, materials, processes, equipment, production, etc.), driving design and process improvements—including product design, process planning, tooling, and quality control methods.

Smart Quality Data Collection

With the introduction of a Quality AI Assistant, the system automates product feature recognition, inspection plan generation, and measurement data integration, significantly improving the efficiency and accuracy of quality data collection and processing.

Data-Driven Zero-Defect Loop

On top of the integrated system, LinkedData embeds its “zero-defect” philosophy into practical operations. With a simplified loop of “trace–contain–alert–prevent,” customers can ensure traceable issues, isolated risks, predictable trends, and sustainable improvements—steadily progressing toward the vision of zero defects.

Strategic Significance and Future Value

The system is now under construction, and the customer has positioned it as the quality cornerstone of its future development. With data-driven management and closed-loop mechanisms, the partnership delivers multiple values:

Consistent Management Implementation: Seamless data integration between R&D and manufacturing, as well as issue linkage across supply chain and after-sales, enabling a truly end-to-end quality loop.

Internal Quality Improvement: Higher closure rates for incoming, in-process, and outgoing inspections; reduced rework and repair rates; and improved production efficiency.

Enhanced Customer Trust: Standardized 8D reports and transparent traceability reduce complaint response times, significantly boosting customer satisfaction.

Upgraded Management Approach: Quality dashboards provide real-time insights for management, enabling data-driven decision-making and the shift from “post-event control” to “preventive management.”

Industry Demonstration Effect: This project will serve as a benchmark for digital quality management in the electrical industry, showcasing how the zero-defect solution strengthens core competitiveness.

Conclusion

Zero defects is not a final destination but a continuous journey of improvement and evolution. The strategic partnership between the public company and LinkedData marks a milestone in building an integrated quality management system. Through consistent data, intelligent analysis, and end-to-end closed-loop management, they are jointly laying down a robust competitive foundation for the future.

This is not only the customer’s vision for quality but also LinkedData’s mission—to “create zero-waste industrial manufacturing.”

0510-8521 1230

0510-8521 1230