Emerson (Copeland): Linkeddata Digital QMS Empowering Zero-Loss Industrial Manufacturing

As the global manufacturing industry moves towards intelligence and digitalization, quality management has become a key factor in enhancing a company’s core competitiveness. In particular, in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) and industrial sectors, where product performance requirements are stringent, quality control directly affects system stability and energy efficiency. Compressors, as the core components of refrigeration systems, demand extreme precision and reliability. Even minor quality deviations can lead to reduced overall efficiency or even customer complaints.

Traditional quality management methods rely on manual inspections and paper-based records, which are prone to delays, data loss, and inefficiencies. These approaches struggle to meet modern lean manufacturing requirements for data traceability and real-time monitoring. As a result, an increasing number of companies are adopting Digital Quality Management Systems (QMS), leveraging data-driven strategies to enhance quality control and ensure product consistency and stability.

Project Background

Copeland Environmental Technologies (Suzhou) Co., Ltd. (formerly Emerson Climate Technologies (Suzhou) Co., Ltd., hereinafter referred to as “Copeland”) specializes in the research, development, and production of scroll compressors, Copeland™ residential air-conditioning compressors, and refrigeration systems. It is a global leader in sustainable solutions for the HVACR and industrial sectors, helping residential, commercial, refrigeration, and industrial customers reduce carbon emissions and improve energy efficiency. As an industry leader, Copeland not only provides high-quality products but is also committed to advancing smart manufacturing transformations to meet the market’s demand for high-efficiency and reliable refrigeration equipment.

With business expansion and the launch of new production facilities, Copeland has set higher requirements for quality management, aiming to overcome the limitations of traditional management methods through digitalization and achieve more precise and efficient quality control.

Challenges in Quality Management

During Copeland’s production and quality inspection processes, several key challenges were identified:

• Inefficient paper-based record management: Large volumes of inspection data were stored in paper archives, making retrieval difficult and increasing the risk of data loss.

• Data silos in measurement equipment: Measurement instrument data could not be directly uploaded to the system, requiring manual transcription, which was both time-consuming and error-prone.

• Difficulties in quality traceability: When quality complaints occurred, tracing records required extensive manual data collection, slowing response times.

• Complex batch management: There was no intuitive tracking of skipped batches, and analyzing past data required extensive searches, reducing management efficiency.

• Cumbersome SPC (Statistical Process Control) data processing: Manual data collection and SPC calculations were time-consuming and prone to errors.

• Lack of transparency in raw material inspection: Supplier inspection batches were difficult to identify, leading to potential delays in detecting quality issues.

LinkedData’s Digital Quality Management Solution

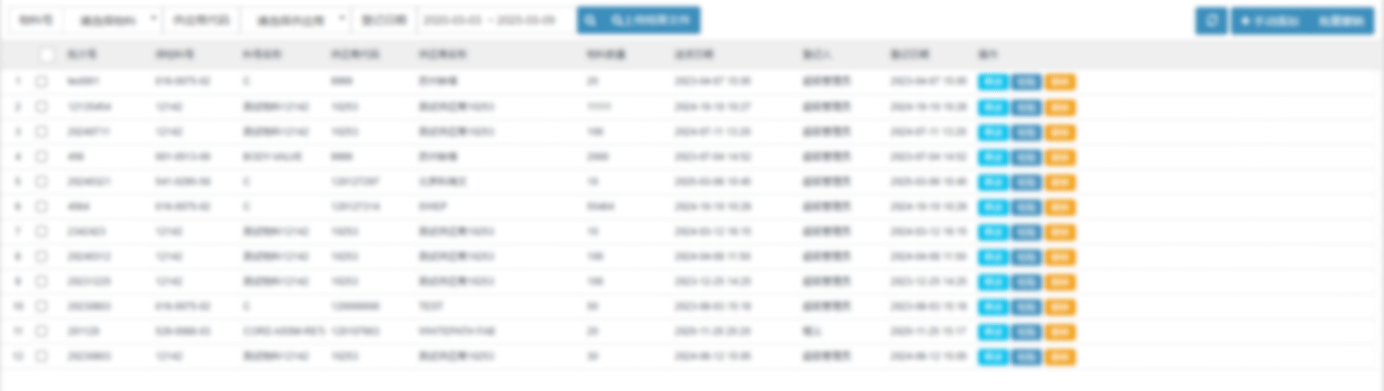

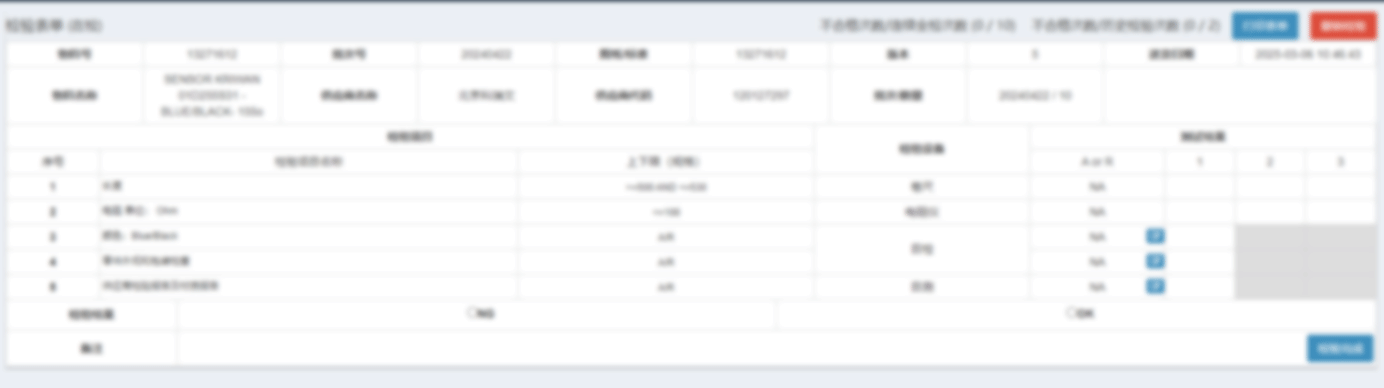

To address these challenges, LinkedData developed an intelligent Quality Management System (QMS) for Copeland, covering the entire value chain from supplier management to production inspections. This system enables measurement equipment connectivity, automated data collection, real-time monitoring, and intelligent analysis. Key features include:

• Automated data collection: Direct integration with measurement devices ensures automatic data uploads, eliminating manual input errors and enhancing inspection accuracy.

• Smart supply chain collaboration: Integration with supply chain databases allows automatic retrieval of incoming material and inspection plans, enabling intelligent batch inspection management.

• Customized quality management: Flexible configuration of inspection plans for different suppliers and materials, supporting custom testing standards, skip-inspection rules, and version control.

• Intelligent SPC data analysis: Real-time data collection and automatic SPC calculations provide visual analytics, supporting continuous quality improvement.

• Electronic dashboard monitoring: On-site digital dashboards display batch inspection statuses and issue real-time alerts, enabling management to quickly respond to quality issues.

Implementation Results

By implementing LinkedData’s Digital Quality Management System, Copeland has achieved significant improvements in quality management:

• Enhanced data management efficiency: All inspection data is stored digitally, eliminating paper records and enabling fast searches and precise traceability.

• Optimized inspection processes: Direct system uploads from measurement equipment reduce manual recording workload and improve data accuracy.

• Accelerated quality traceability: Quality complaints can be quickly resolved with instant access to historical data.

• Intelligent quality analysis: Automated SPC calculations support data-driven decision-making, continuously optimizing quality control strategies.

• Improved production coordination: Real-time visibility into batch inspection statuses allows management to monitor production quality and optimize workflow.

Copeland’s success demonstrates that digital quality management is not just a production upgrade but a critical enabler of enterprise competitiveness. In industries such as refrigeration, automotive components, and precision manufacturing, the accuracy and efficiency of quality control directly impact product performance and customer satisfaction. By deeply integrating IoT technologies with quality management processes, LinkedData will continue to empower manufacturing enterprises towards higher quality and smarter production, realizing the vision of “Zero-Loss Industrial Manufacturing.”

0510-8521 1230

0510-8521 1230