Downtime Is No Longer a Challenge! How Digital Management Enables Effective Problem Resolution

In our previous article, we explored how digital tools can help alleviate bottlenecks in the workshop and enhance production efficiency. However, what we truly need is effective knowledge management. The problem itself is not the biggest issue—the real challenge is when problems are not properly managed.

Classification and Rational Management of Downtime

Today, I want to share how we have systematically defined and categorized downtime in our production setup. Many companies tend to lump all downtime together as “losses.” However, through classification, we can more accurately identify the root causes of each issue and determine the appropriate solutions. This approach to categorization brings significant benefits.

For instance, planned downtime is often considered an acceptable loss, but this “acceptability” must be clearly defined. Meal breaks, such as lunch and dinner times for employees, can be excluded from downtime records. This way, systems like Andon or other monitoring tools will not mistakenly log these breaks as problem-related losses.

Changeover downtime is another typical example. When switching from Model A to Model B, it is often viewed as a loss, but in reality, it represents an opportunity. Without such changeovers, achieving flexibility in delivery would be difficult. Therefore, it is essential to establish clear benchmarks for acceptable changeover times and standardize management practices. We will continue sharing insights on how to manage this process effectively, defining standard versus actual changeover times.

Additionally, technical downtime is a common issue often associated with equipment failures, while organizational downtime can stem from material shortages, workforce gaps, and other production-related factors. Quality downtime involves product rework or quality-related issues, such as test setups and quality control procedures. These factors should be categorized under quality downtime. Finally, scheduled maintenance requires systematic management similar to other forms of downtime.

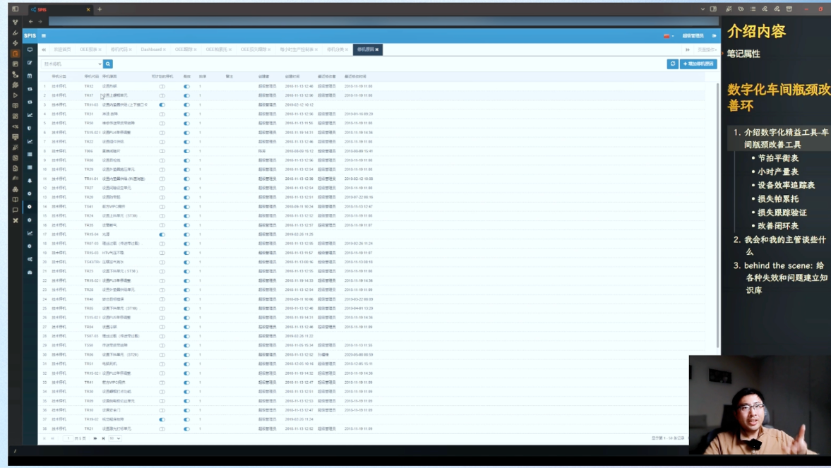

With these broad categories in place, we can further define the specific causes of each downtime type and classify them systematically. For example, code TR12 could represent a specific setup issue. Such categorization enables more efficient record-keeping and management.

Using standardized codes not only facilitates quick recording but also allows for horizontal comparisons across multiple factories or production sites. This coding approach helps benchmark performance, identify discrepancies, and take timely corrective actions.

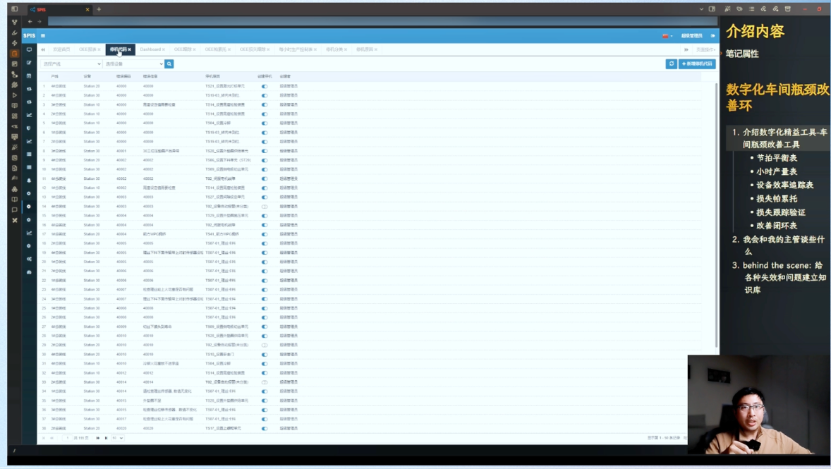

Furthermore, these codes serve more than just classification and documentation purposes—they can also be integrated with Industrial Internet of Things (IoT) systems. In certain scenarios, IoT can automatically capture downtime data, reducing reliance on manual entries. This is particularly valuable for short downtime periods, where human recording may be inaccurate.

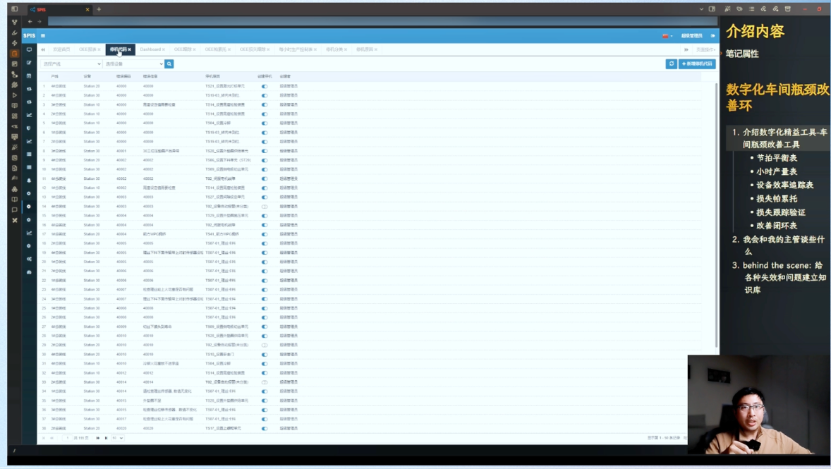

For automated production lines or shared workstations, IoT systems can monitor alarm points via Programmable Logic Controllers (PLCs) and sensors. When downtime occurs, the system automatically logs the event and links it to the relevant downtime code. For example, in our Production Control (PC) system, error codes such as 40005 or 40006 are used to identify specific issues. When the IoT system detects these error codes, it attributes the corresponding timestamps and causes to the downtime records. This ensures data accuracy and provides real-time insights, making downtime management clearer and more efficient.

Building a Knowledge Base with Digital Lean Management

Even though I may not fully understand every 400-series error code, I do know that it represents an issue related to “wiring.” This highlights an important point—we can visualize business processes through a digital lean system. To achieve this, businesses must first standardize their operational logic, definitions, and terminology, establishing a unified knowledge base. These knowledge bases, with their standardized codes and definitions, form a shared framework within the organization.

By integrating IoT with digital lean management systems, we can automate the entire process—from downtime logging to root cause analysis. The advantage of such a system is that it allows us to monitor downtime causes in real-time and continuously optimize operations based on data. This not only provides a clearer view of production bottlenecks but also fosters a shared knowledge base across the company.

Moving forward, we should link everyday, weekly, and monthly problem-solving solutions to these downtime codes. Over time, this integration will deepen our understanding of various challenges and drive significant value for the organization.

Years of experience have taught me that meticulous management and optimization of every detail are highly meaningful. With the advancements in digital technology, these efforts are becoming more seamless and efficient than ever.

I look forward to further discussions and exchanges on how digital lean management can benefit more individuals and businesses. Thank you all for your attention and participation!

0510-8521 1230

0510-8521 1230