LinkedData’s Data Acquisition and OEE Analysis System Powers Digital Transformation for Packaging Giant Amcor

As globalization accelerates and consumer demands diversify, the traditional packaging industry faces a range of complex challenges. These include stricter environmental regulations, growing expectations for high-quality, high-efficiency packaging solutions, and an urgent need for digital transformation within the sector. Amid this landscape, Amcor, a global leader in packaging, has proactively embraced digital upgrades to maintain its competitive edge in the evolving market.

Project Background

Jiangyin Amcor Flexible Packaging Co., Ltd., and Jiangyin Amcor New Material Co., Ltd. are two key production facilities of Amcor in Eastern China. Their main products include chip packaging, toothpaste tubes, colorful flexible packaging, and pharmaceutical packaging, serving the fast-moving consumer goods (FMCG) and pharmaceutical sectors. These products involve complex processes such as film blowing, slitting, extrusion coating, and rewinding, with a diverse array of equipment and intricate product formulations.

To tackle increasing market competition and establish a high-quality, high-efficiency production model, Amcor sought to implement a digital transformation. The primary challenges included:

• Cumbersome paper-based records: Paper records were time-consuming to manage, prone to loss, and difficult to access.

• Opaque data: Equipment status relied on manual input, which was often incomplete or inaccurate.

• Incomplete downtime tracking: Small stops and equipment failures were not recorded comprehensively, hindering management insights.

• Lack of real-time alerts and feedback: Delayed responses to equipment anomalies or stoppages affected efficiency.

• Low efficiency in manual processes: OEE calculations and SPC data processing relied on labor-intensive manual work, limiting accuracy and impeding improvement efforts.

LinkedData’s Solution: OT + IT Integration for Digital Manufacturing

Amcor partnered with LinkedData to implement a comprehensive OT + IT data acquisition and OEE analysis system. This solution aimed to enhance production efficiency and support the creation of an Industry 4.0 benchmark factory. The project began in 2022 and was implemented across multiple factories in phases, covering more than 75 pieces of equipment and driving the digital transformation of Amcor’s operations.

The solution includes modules for equipment connectivity, real-time monitoring and alerts, production parameter tracking, product throughput monitoring, OEE and customized loss identification, and real-time reporting.

Core Functions of the Data Acquisition and OEE Analysis System

Core Features and Highlights

1. Real-time equipment and process data acquisition: IoT technology ensures immediate and comprehensive data capture for digital monitoring.

2. Automated OEE calculations and loss analysis: The system uses real-time data to compute OEE and identify losses, providing actionable feedback for efficiency improvements.

3. WCM-driven continuous improvement: Leveraging World Class Manufacturing (WCM) methodologies, the system enables sustained enhancements in equipment performance and production processes.

Project Outcomes

1. Equipment Connectivity and Real-Time Monitoring

• Integrated data collection from over 75 pieces of equipment across two factories, covering key operational parameters.

Real-Time Monitoring of Process Parameters

• Monitored critical process parameters, such as tension, pressure, and temperature, in real time.

• Linked 10 electronic scales to collect accurate product weight data, meeting the stringent quality demands of FMCG packaging.

2. System Integration and Data Sharing

• Seamlessly connected the system with Amcor’s ERP and barcode systems, enabling single sign-on (SSO) for improved user convenience.

• Provided transparent data sharing across work hours, equipment status, and production metrics, streamlining workflows.

Real-Time Production Shift Information

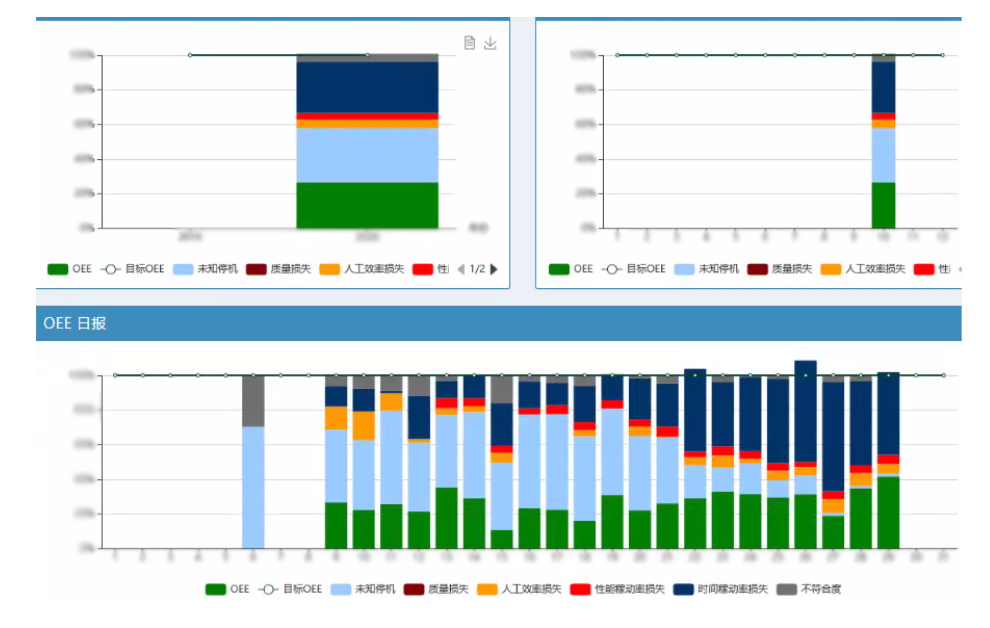

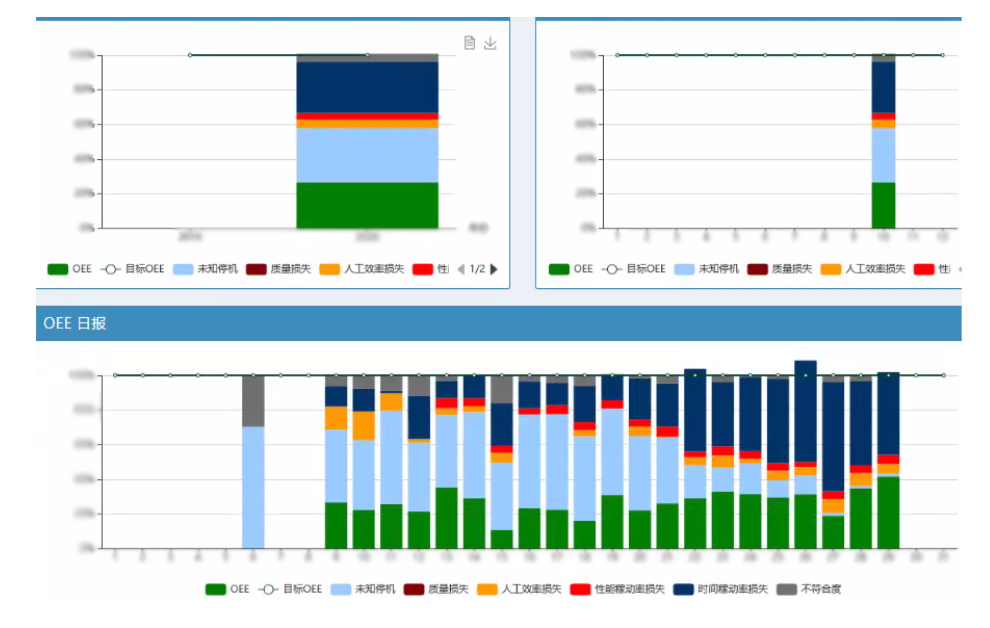

3. OEE Analysis and Visualization

• Automatically generated OEE and loss tracking reports with transparent and intuitive data visualization.

OEE and Loss Tracking

• Utilized Pareto analysis to pinpoint areas of inefficiency, supporting targeted improvements.

• Offered BI tools integration, delivering deep data insights for executive decision-making.

4. Efficiency Gains and Sustainability Practices

• Reduced paper-based record-keeping and manual labor, aligning with sustainability goals by cutting resource waste.

• Improved OEE efficiency across production lines through continuous improvement initiatives driven by WCM principles.

Transforming Packaging with Smart Manufacturing

LinkedData’s digital solution enabled Amcor to address industry challenges and take a significant step from traditional manufacturing to smart factory operations. Real-time data acquisition eliminated information silos, ensuring accurate and timely insights. Automated OEE analysis and loss tracking minimized reliance on manual processes, maximizing equipment utilization.

These advancements not only enhanced Amcor’s production efficiency and quality management but also solidified its leadership in the FMCG packaging sector. As Industry 4.0 and smart manufacturing evolve, the partnership between Amcor and LinkedData will continue to drive innovation and foster the digital transformation of the packaging industry.

0510-8521 1230

0510-8521 1230