Registration | Industrial DataSpace Series: Automotive Parts Industry Digital Transformation Seminar

Page View

Time 2024-12-11

The rapid rise of new energy vehicles is accelerating the reshaping of the automotive parts industry’s value chain while also bringing new challenges. “Intensified competition” and “intelligence” have become key terms in the industry’s development. How to achieve cost reduction and efficiency improvement amidst fierce competition has become a challenge every enterprise must face.

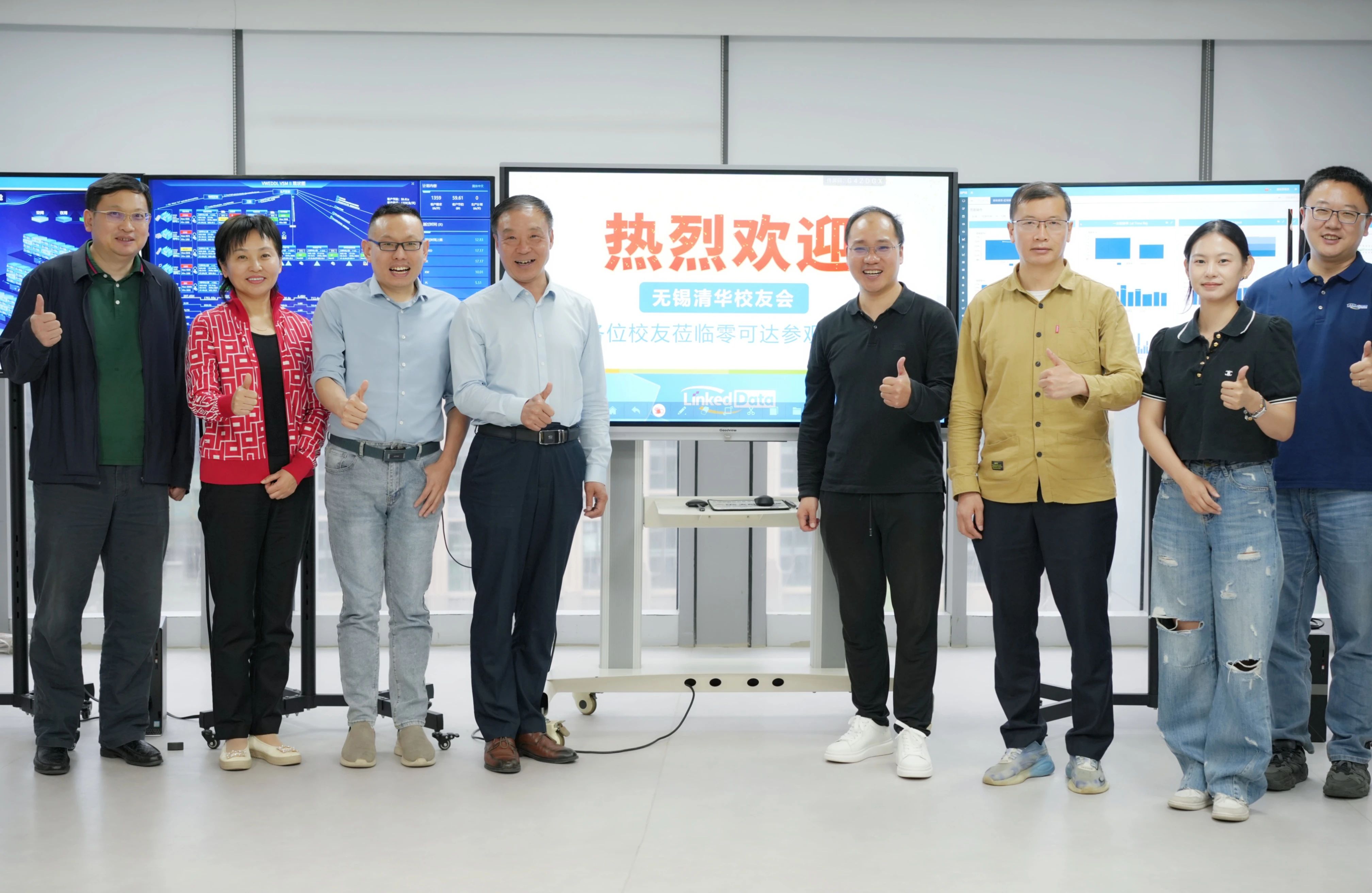

LinkedData, as an industry expert in smart factory solutions, has helped numerous customers improve their competitiveness with extensive experience in digital transformation. In this seminar, we invite industry heavyweights to jointly explore the latest digital transformation practices in the automotive parts industry, providing participants with practical solutions and ideas.

We cordially invite you to join us and explore the future of the industry!

Date

December 19, 2024 (Thursday) 13:00-17:30

Location

Twin B Tower, National Software Park, Xinwu District, Wuxi

LinkedData Future Factory

This is an exclusive seminar with only 30 seats available. Scan the QR code to register now (requires approval).

• In-depth understanding of the digital transformation status of the automotive parts industry

• Insight into new trends in smart factory construction

• Exploring best practices in lean cost reduction and digital efficiency improvement

• First-hand experience of LinkedData’s leading technologies at the Future Factory

• Networking with top industry experts and accessing practical solutions

13:00 - 13:30 | Registration

13:30 - 13:35 | Opening Remarks

13:35 - 14:05 | New Trends in Smart Factory Construction

Founder & CEO, LinkedData

Bachelor’s in Industrial Engineering from Tsinghua University, Master’s in Mechanical Engineering, Executive Board Member of the Automotive Intelligent Manufacturing Technology Center, and Senior Expert in the Chinese Automotive Industry’s Intelligent Manufacturing Expert Database. Xiang has nearly 20 years of experience in smart factory construction and digital transformation, having led more than 50 smart factory projects.

Building smart factories based on data infrastructure to break down information silos and fully leverage data assets. This session will cover LinkedData’s smart factory solution architecture and its core features.

14:05 - 14:45 | Lean Cost Reduction, Digital Efficiency Improvement

Supply Chain Consultant from a Top 1 Automotive Parmatchts Manufacturer

• Core strategies for lean cost reduction

• Empowering lean improvements through digitalization

• How logistics automation boosts efficiency

• Case study: Successful practices in cost reduction and efficiency improvement

• Future trends: The integration of lean and digitalization

14:45 - 15:15 | LinkedData Future Factory Demonstration and Experience

Vice General Manager, LinkedData

Over 20 years of operations and digital transformation experience. Feng has worked at companies like Delphi, Bosch, and FaworTech, driving the transformation in automotive parts, supply chain, and industrial controllers. He is a seasoned expert in Industry 4.0 and AI applications in industry.

Experience firsthand the technologies of smart logistics, digital twins, precise traceability, and flexible robotics, and see how IT & OT convergence improves factory efficiency.

15:15 - 15:30 | Tea break

15:30 - 16:00 | Complete Analysis of OEE Improvement Strategies

Vice General Manager, LinkedData

Over 20 years of operations and digital transformation experience. Feng has worked at companies like Delphi, Bosch, and FaworTech, driving the transformation in automotive parts, supply chain, and industrial controllers. He is a seasoned expert in Industry 4.0 and AI applications in industry.

Experience firsthand the technologies of smart logistics, digital twins, precise traceability, and flexible robotics, and see how IT & OT convergence improves factory efficiency.

16:00 - 16:30 | Efficiency Improvement Practices at a German Engine Plant

Vice General Manager,LinkedData

Graduated from Tsinghua University, with over 20 years of experience in automotive and parts industry operations. Yan has worked in leadership roles at companies like Nexperia and Bosch, and as the Deputy General Manager of the Xiaopeng Motors manufacturing center.

How to improve personnel efficiency by 5% using smart standardized systems, reducing throughput time by 40% with digital value streams, and optimizing both personnel and throughput time through digital tools.

16:30 - 16:50 | Exploring AI Applications in Smart Factories—AI Large Models for Easier Equipment Maintenance

Technical Director,Linkeddata

Former Senior Development Supervisor at Alibaba Cloud, Goldwind Technology, and Taihu Cloud Computing, dedicated to staying at the forefront of Industry 4.0 technologies, such as IoT, big data analytics, and artificial intelligence, and applying them to smart factory solutions.

This session will explore new maintenance models empowered by AI, focusing on the application of AI large models in equipment maintenance. It will demonstrate how intelligent prediction, precise diagnostics, and autonomous optimization can simplify maintenance processes, reduce operational costs, and significantly improve equipment reliability.

16:50 - 17:30 | LinkedData Application Market Tour and Open Networking

• Practical Insights: Top experts sharing hands-on experience, covering the latest trends in smart factories and successful case studies.

• Immersive Experience: Deep dive into the innovative technologies of the Future Factory and witness the tangible results of digital transformation.

• Targeted Networking: Meet industry peers and senior experts face-to-face, fostering new collaboration opportunities.

This is an exclusive seminar with only 30 seats available. Scan the QR code to register now (requires approval).

0510-8521 1230

0510-8521 1230