In the wave of digital transformation in manufacturing, data has become one of the most important production factors for enterprises. Every machine, every process, and every inspection on the shop floor generates massive amounts of information. Companies hope to use this data to improve efficiency, ensure quality, and optimize decision-making. Yet in reality, they often find that despite the abundance of data, it struggles to deliver real value. The root cause does not lie in the quantity of data, but in the lack of consistency across different systems, levels, and stages. Only when data remains unified throughout the entire chain can digitalization truly take root, and only then can data become a reliable foundation for decision-making and optimization.

Why do enterprises feel their data is untrustworthy?

In the early stages of digitalization, enterprises often face the problem of “too many versions.” Product codes may be inconsistent between ERP and MES systems; production reports may not match what is happening on the shop floor; the data presented at group-level meetings may differ from what frontline staff perceive; and different departments may define the same metrics in different ways. These seemingly minor discrepancies ultimately prevent management from making accurate, data-driven decisions, thereby greatly reducing the value of data.

LinkedData’s answer: Consistency is the core value

At LinkedData, we believe the true value of digitalization does not lie in simply “having data,” but in whether data can remain consistent and be continuously transmitted across all stages. The transmission of data consistency does not merely mean numerical equality—it means that data retains the same origin, meaning, and definition across different systems, levels, and stages. From the moment data is generated at the source, through each layer of aggregation, and across system integrations, it must preserve logical and semantic coherence to build a complete and trustworthy data chain for the enterprise.

Vertical transmission: A true reflection from shop floor to group level

Vertically, an intelligent factory must ensure that data originates from the shop floor and flows seamlessly upward to workshops, plants, and ultimately the group level—without being artificially “re-processed.” For example, process parameters collected on the production line can be cleansed, modeled, and then directly integrated into the factory-level MOM system, eventually appearing in group-level BI reports. This ensures that what management sees is not a “polished” version, but the natural extension of raw shop floor data within a unified model. Only in this way can leaders truly grasp the reality of operations.

Horizontal integration: A unified language across systems

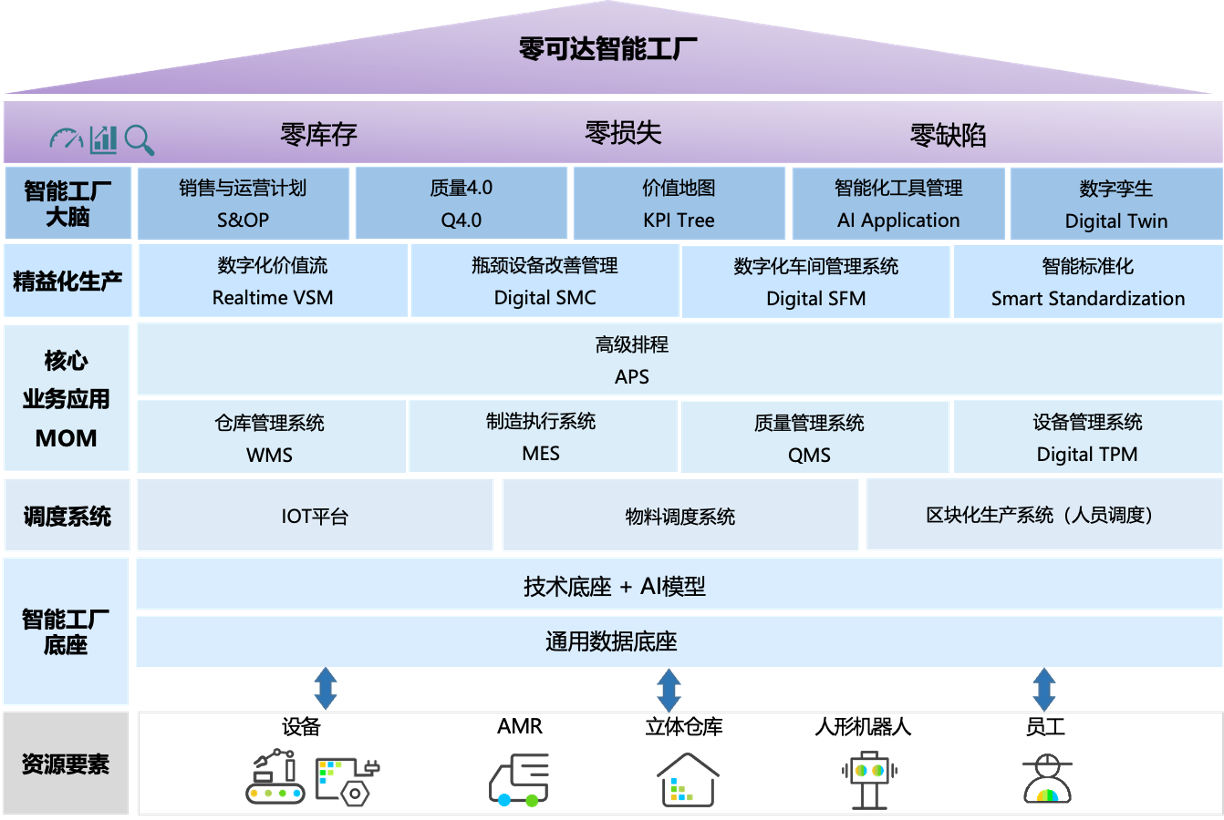

Horizontally, most enterprises operate with multiple parallel systems. ERP manages resources, MES focuses on execution, QMS on quality, WMS on logistics, while IoT platforms collect equipment and environmental data. If these systems do not share a consistent data framework, each department ends up with “its own version of the truth,” weakening collaboration. LinkedData addresses this challenge with its intelligent factory foundation and unified data architecture. Whether it is master data such as material or batch numbers, or business data such as order status or inventory information, all are centrally managed and consistently shared. As a result, different departments and roles no longer need to rely on manual reconciliation or subjective interpretation—they can work with the same reliable set of data.

The time dimension: Ensuring continuity across the product lifecycle

Furthermore, data consistency must extend across time, not just space. A product moves from R&D, through pilot production, to mass production, with parameters and processes evolving along the way. If data cannot flow seamlessly across these stages, “gaps” appear, leaving later stages without the necessary context. LinkedData’s solutions ensure that parameters defined in R&D are validated and refined during pilot runs, then naturally passed on to mass production. When problems occur, enterprises no longer need to re-collect information; they can trace root causes directly along the same data chain. This lifecycle-wide consistency lays the groundwork for digital twins and advanced analytics.

Semantic alignment: Ensuring consistent business logic behind the numbers

Maintaining data consistency is not just about aligning numbers—it also requires semantic unity. For example, if the definition of “defect rate” in a quality system differs from those in production or finance systems, the same metric may yield multiple interpretations. LinkedData addresses this by embedding industry best practices and quality management principles—such as Bosch’s 14Q methodology—into its systems. These semantic rules ensure that data is not only numerically aligned but also logically consistent across the enterprise.

From consistency to intelligence: The path toward zero-waste manufacturing

For LinkedData, the transmission of data consistency is not the end goal, but the starting point of a higher stage of intelligent manufacturing. Only when data is credible and complete can AI technologies truly support business optimization and decision-making. Only when consistency is preserved across the entire chain can digitalization deliver continuous improvement and enable the vision of zero-loss manufacturing.

Creating zero-waste manufacturing is LinkedData’s mission—and the transmission of data consistency is the foundation upon which this mission is built.

Start Now! Improve Order Delivery Efficiency Immediately!

Contact us and explore order delivery efficiency improvement with LinkedData digital transformation experts.

Request a Demo

0510-8521 1230

0510-8521 1230